K&N Offers Universal Electric Fuel Pumps in Four Different Styles for Gas & Diesel

- Oct 9, 2014

Traditionally fuel pumps were mechanical and driven by the rotation of the engine itself. A diaphragm inside the mechanical pump created suction drawing fuel from the tank to the carburetor. The action of the mechanical fuel pump is similar to that of a piston moving inside an engine. Over time, or due to heat, the diaphragm can leak or fail completely. This can cause drivability issues, or in the case of complete pump failure, a vehicle that will not run.

As cars moved from carburetors to fuel injection, mechanical fuel pumps were replaced by electric fuel pumps due to the higher fuel pressures required by fuel injection. An electric fuel pump has several advantages over a mechanical fuel pump even for carbureted applications. An electric fuel pump doesn't rely on the speed of the engine to move fuel. This results in even, steady, fuel pressure throughout the system. Also, because a mechanical fuel pump is bolted to the engine block and exposed to high temperatures this can cause fuel to vaporize. Because a mechanical fuel pump is designed to move liquids, it cannot move a gas resulting in vapor lock. A properly installed electric fuel pump will virtually eliminate the possibility of vapor lock.

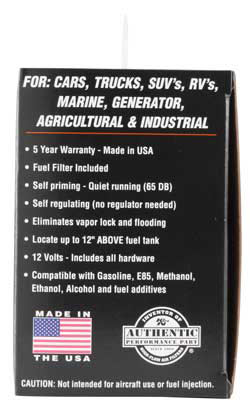

K&N electric fuel pumps take electric pump advantages to a higher level. State of the art sealed electronics are contained in the corrosion resistant composite case housing. K&N electronic fuel pumps do not have bearings, electrical contacts, or diaphragms to wear out or fatigue. They are performance rated for 6,000 hours and can last four to five times longer than many other electric fuel pumps. The entire unit is light weight at only 18 ounces and compact, measuring just 3 inches. Installation is simple using two included bolts, and the two color coded wires makes getting 12V power to the pump stress-free. K&N electric pumps are self-priming and self-regulating eliminating the need for a separate fuel pressure regulator. K&N electric fuel pumps are available in four variations depending on the fuel pressure needs of different engine applications. K&N Fuel Pump 81-0400 is rated at 1.0-2.0 PSI, or 15 gallons per hour. This pump is best suited for small engine applications, such as generators, power equipment, or motorcycle and ATV use. Fuel Pump 81-0401 is rated at 1.5-4.0 PSI/25 GPH and will work well with carbureted four and six-cylinder automotive applications. Part number 81-0402 has a 4.0-7.0 PSI/32 GPH rating. 81-0402 is ideal for typical gasoline V8 powered car and truck use. K&N Fuel Pump 81-0403 is being called a diesel fuel pump because of the higher fuel pressure needs of diesel engines. 81-0403 is rated at 9.0-11.5 PSI/34 GPH. Both 81-0400 and 81-0403 have an internal check valve to help keep the fuel system primed when powered off. This is critical in diesel or powersports applications.

All four pumps are compatible with gasoline, diesel, biodiesel, E85, blended alcohol, and fuel additives. K&N electric fuel pumps can be used on all carburetor equipped engines as well as a lift pump for diesel fuel injection systems. Each pump includes a disposable fuel filter which threads into the pump's inlet, and a 1/8" NPT threaded hose barb fitting for the outlet. The included fuel filter and hose barb will work with 3/8" fuel line, or can be swapped out for different diameter hose fittings, sold separately. Fuel pumps 81-0401 and 81-0402 can be placed up to 12" above the fuel tank. 81-0400 can be placed up to 24" above the fuel tank, and the diesel electric fuel pump, number 81-0403, can be located 50" above the fuel tank. K&N electric fuel pumps are manufactured in the U.S.A and are backed by a 5 year warranty. K&N has thousands of universal and custom performance parts or use the vehicle specific search tool to find parts specifically designed for your car, truck, motorcycle or even industrial equipment. |

|||||

|

|||||